Every product and service has a supply chain. Managing that chain is the foundation of efficient business operations.

The key is to understand the different steps in the chain and adopt strategies that drive cost savings and customer satisfaction.

In this article, you’ll discover what supply chain management is and why it’s critical for business success. You’ll also learn how to harness its full potential to streamline your operations, improve profitability and stay competitive.

Supply chain management meaning: Supply chain management (SCM) refers to coordinating all activities related to the production and distribution of goods. SCM is an all-encompassing term that covers the entire product lifecycle, from initial planning and procurement through to delivery and returns.

While supply chain management denotes physical goods, its meaning has expanded to include managing the flow of services, finances and data.

Almost every product or service is the work of multiple businesses coming together.

For example, even for something as simple as a cup of coffee, farmers must first harvest the coffee beans. Someone else processes and roasts the beans before distributing them to stores and cafes.

When it comes to more complex products, such as smartphones or cars, hundreds of companies may be involved in the process.

Multiple stakeholders (including suppliers, manufacturers, distributors and retailers) must collaborate to create a supply chain. By managing this chain more effectively, businesses can meet customer demand while controlling costs.

According to Dr. Douglas Lambert, the supply chain is a network of companies, and SCM means building cross-functional relationships with customers and suppliers in that network.

Successful SCM involves overseeing these relationships to keep materials flowing smoothly across the supply chain, minimize delays and improve profitability.

What are the different types of supply chain models?

There are several supply chain models, each with different strengths for different industries and priorities.

Agile supply chain

If you’re working in an industry where it’s difficult to predict customer demand, an agile supply chain model helps maintain flexibility. The model enables you to adapt to market shifts as they occur.

For example, e-commerce companies and retailers can quickly adjust their inventory and sourcing strategies to respond to sudden spikes in demand, such as during sales promotions, flash sales or seasonal events.

Agile supply chains can ramp production up or down quickly in response to changes, focusing on reducing lead times to meet demand as soon as possible. An agile model requires close collaboration with suppliers and partners to facilitate any necessary changes without delay.

Continuous flow supply chain

At the other end of the spectrum, a continuous flow supply chain model is ideal for businesses with consistent demand, such as companies that produce commodities or bulk products (e.g., food, chemicals, etc.) The goal is to maintain an ongoing, stable flow of goods with minimal interruptions.

The continuous flow model operates best when demand is predictable and manufacturers can plan production far in advance. However, it’s less adaptable when unexpected changes or other disruptions occur. The model relies on accurate forecasting, making it ideal for companies that produce standardized products on a large scale.

Fast supply chain

The fast supply chain model is all about speed and responsiveness, focusing on quick turnaround times for product delivery. This model is common in industries with short product lifecycles, such as fast fashion, where staying ahead of trends is critical, and products must reach the market quickly.

The fast supply chain aims to reduce lead times and expedite production to meet immediate customer demands. While the agile model is designed primarily for flexibility, the fast model prioritizes speed over every other factor.

Efficient chain

An efficient supply chain model aims to produce and deliver goods at the lowest possible cost without compromising quality or service.

The efficient model works best when demand is relatively stable and predictable, allowing for cost-saving measures like bulk purchasing and long-term supplier contracts. The model often serves highly competitive industries with slim profit margins, such as consumer goods or electronics manufacturing.

The importance of effective supply chain management

SCM no longer goes unseen by customers. Millennial and Gen Z buyers are reshaping supply chains, preferring ethically sourced and sustainably cared-for products making their way to the consumer.

Retailers looking for a competitive advantage are listening, too. For example, Austral Fisheries labels each portion of fish with a QR code showing the journey from ocean to plate, traced back to each fish.

SCM’s impact on customer experience and a company’s bottom line is impossible to ignore. Disruptions to the supply chain on the other side of the globe can affect your customers and profits.

Any business that relies on other companies for supply and distribution should ensure their supply chain operations are robust and resilient in the event of any potential disruption or other changes.

Here are just some of the benefits that come with an efficient and well-managed supply chain.

Improved operational efficiency and profitability

One key goal of SCM is to streamline operations across the entire supply network. Effective SCM ensures the right products are available in the correct quantity at the right place and time, reducing bottlenecks and preventing expensive delays.

For example, using real-time data and advanced analytics enables you to adjust production schedules and manage inventory levels based on actual customer demand, avoiding overproduction or running out of stock.

Optimizing supply chain processes, such as demand forecasting, sourcing and procurement, can improve cash flow while reducing unnecessary costs.

Proper inventory management through apps like Cloudify Unleashed prevents capital wasting on excess stock, while efficient logistics management reduces transport and storage costs.

Additionally, effective supplier relationships enable you to negotiate better pricing, improve payment terms and secure a more reliable goods supply. In the long term, these improvements result in healthier profit margins and better financial stability.

Resilience and risk management

Supply chain disruptions – such as those caused by global pandemics, political instability or natural disasters – can have a massive impact on businesses.

For example, when the Ever Given container ship blocked the Suez Canal for six days, it held up more than 400 vessels (worth almost $60 billion in trade) and caused an estimated 60-day shipping delay.

An effective supply chain management strategy is important to any integrated risk management system. You can build more resilient global supply chains by identifying potential risks and developing relevant contingency plans.

By diversifying suppliers or establishing partnerships in multiple regions, you minimize the impact of any unexpected disruptions on your supply chain.

Technology, such as AI and machine learning, can also help predict potential risks and allow for faster, data-driven decision-making during crises.

For example, American Airlines uses machine learning to predict the likelihood that a cargo shipment will show up on time, flagging risky shipments and enabling them to optimize shipment planning.

Sustainability and environmental responsibility

Consumers are demanding more sustainable products and eco-friendly business practices. A McKinsey study found that products with environmental, social and governance-related (ESG) claims grew by an average of 28% compared to 20% for products without such claims.

For example, Unilever found that their Sustainable Living brands expanded 69% faster than the rest of their business and were responsible for 75% of the company’s overall growth.

An adequate supply chain can significantly reduce your environmental impact by minimizing waste and optimizing logistics. Sustainability initiatives, such as reducing carbon emissions from transport or implementing circular supply chain models focused on recycling and reusing materials, help you reduce your ecological footprint.

This sustainability drive benefits the environment, enhances your brand’s reputation and meets the growing consumer demand for ethical practices.

Customer satisfaction and competitive advantage

Ensuring your products are consistently available while delivering orders accurately and on time contributes to a positive customer experience.

A strong supply chain also includes rigorous quality checks at every stage so that the final product meets customer expectations. Maintaining quality standards increases customer satisfaction, leading to fewer returns and complaints.

You can improve customer loyalty and reinforce your market position by aligning supply chain operations with customer expectations.

Moreover, when you’ve taken the time to optimize your supply chain, you can react more quickly to market changes and deliver a better service than competitors relying on inefficient supply chains.

The 5 key components of supply chain management

SCM involves multiple connected processes, each essential for the smooth flow of goods from raw materials to the final product.

The five key components below form the backbone of effective strategic supply chain management.

1. Planning

An efficient supply chain requires careful planning. Start by using historical data (e.g., sales trends, seasonal variations, etc.) and customer insights to better understand future demand for your product or service.

Consider how you could meet that demand without incurring unnecessary costs. Determine what resources (including raw materials, capital and labor) you need and their distribution across the supply chain to meet your business objectives.

Enterprise resource planning (ERP) software can help you analyze the available data and make smarter decisions for improved supply chain planning.

For example, your procurement teams could use your ERP system to automate purchase requests and coordinate with suppliers to ensure your stock levels meet your needs. Manufacturing teams can see real-time information on customer demand and resource management.

2. Sourcing

Sourcing involves identifying and selecting the suppliers who provide the raw materials, components or services necessary to create your final product.

Focusing on finding the cheapest option may result in inferior materials and increased customer complaints. While price is important, you should also evaluate suppliers based on their quality, reliability and ability to meet your sustainability goals.

Finding the right supplier goes beyond a transactional arrangement; suppliers must collaborate with you to deliver the best results. Strong supplier relationships reduce the risk of unexpected disruptions as they’re more likely to prioritize your orders.

If there’s a delay, having an established relationship means you’ll be more likely to work together to find a solution. As part of your risk management plan, you should also have contingency plans such as alternative sources or a clearly defined safety stock for critical materials.

Once you’ve found your ideal suppliers, monitor their performance to verify that they meet your requirements. Use your ERP or supply chain software to monitor metrics such as on-time delivery rates and defect rates.

3. Manufacturing

Many businesses create value through manufacturing, transforming raw materials into finished products. Simple steps like using your ERP system to schedule production around customer demand will help you produce the right amount of product without overproduction or shortages.

Monitor production with a manufacturing execution system (MES) as part of your production management process. Use real-time analytics to get instant feedback on production and equipment performance.

As a result, you can identify any potential production issues before they become serious problems. For instance, you can assess whether you need to change your workflow or replace a piece of equipment.

Increased visibility into your manufacturing process minimizes downtime and ensures consistent output quality.

4. Delivery

Delivery covers all the steps involved in getting your finished goods to the customer, including warehousing, transportation and distribution.

Before you dispatch anything, you need to store it. Use an inventory management system (IMS) to keep track of stock levels in real time. Accurate stock figures mean you can always be confident you have enough goods on hand while minimizing unnecessary storage costs.

The next step is getting the goods from your premises to the next step in the chain, whether to a retailer or directly to the customer.

Just as you carefully selected your raw material suppliers, take your time to choose the right logistics providers. Are they properly certified and insured to handle deliveries on your behalf? Are they able to deliver your goods securely and on time?

Efficient delivery ensures products are where they need to be at the right time while minimizing storage and transport costs.

5. Returns

Sooner or later, a customer will want to return a product. Returns management (also known as reverse logistics) covers handling returns, repairs or disposal.

An efficient returns system provides a stress-free process for customers while enabling you to potentially resell the returned product.

Start by having defined processes to manage returns, including how customers can initiate one and what you’ll do with the returned items.

For example, rather than making customers phone and talk to a support agent, they could request a return and print out a pre-paid returns label directly from your website.

Grade returned items by condition, such as whether you can repackage and resell them or if they require repair or disposal. Automatically assign the appropriate workflow accordingly.

Clear return policies and efficient processing help you navigate a potentially negative situation successfully, minimizing waste and showing your commitment to providing the best possible customer experience.

The role of technology in supply chain management

While supply chains have been around for as long as there have been products to sell, recent technological advancements are revolutionizing how companies manage them.

By embracing these innovations, you can enhance every step in the chain even more effectively.

Automation and robotics

From warehousing to production lines, automation can help businesses improve their processes in various ways. Workflow automation systems can handle tasks like data entry, transactional messaging and inventory management faster and more accurately.

Automation lowers labor costs and mitigates the risk of human errors by reducing reliance on manual labor. Robotics, in particular, can perform repetitive tasks such as picking and packing in distribution centers, speeding up operations and reducing operational costs.

For example, Ocado’s robotic picker uses machine vision and advanced sensing to pack grocery items efficiently into bags.

Artificial intelligence (AI) and machine learning

AI and machine learning have regularly made headlines for the last few years as their capabilities keep increasing. Pipedrive’s 2024 State of Sales and Marketing Report found that 35% of sales and marketing professionals use AI tools.

The technology now supports supply chain management to drive smarter decision-making. AI analyzes vast amounts of data to help businesses improve their demand planning and production scheduling.

AI-powered systems can monitor equipment performance in real time and predict when it requires maintenance, reducing downtime and improving manufacturing efficiency. Machine learning algorithms can also help identify patterns in customer behavior, enabling you to adjust your supply chain strategies accordingly.

Amazon now uses an AI model named Project P.I. (which stands for “private investigator”) to spot damaged or incorrect items before dispatch. The technology also helps the company identify the root cause of the defect and take preventative measures.

The state of sales and marketing 2024

Blockchain technology

For many businesses, blockchain hasn’t reached the same popularity as other technologies. The Pipedrive report found that only 1% of respondents have implemented blockchain in their sales process in the last two years.

However, blockchain has significant implications for supply chain optimization. By providing a decentralized and secure transaction record, the technology enables businesses to track the movement of goods across the supply chain, from sourcing raw materials to delivering finished products.

Blockchain enables complete visibility into the origins and movement of goods – which is particularly valuable in industries like food, pharmaceuticals and luxury goods – where product authenticity is critical. The permanent nature of blockchain makes it extremely difficult for any party to alter records, reducing the risk of fraud or counterfeit goods entering the supply chain.

For example, Walmart has been using blockchain technology to enhance ingredient traceability for the farms that harvest them.

How CRM software supports supply chain management

Customer relationship management (CRM) software typically involves sales and marketing but also plays a crucial role in supply chain management software. Integrating your CRM and SCM can improve coordination and create more efficient supply chains.

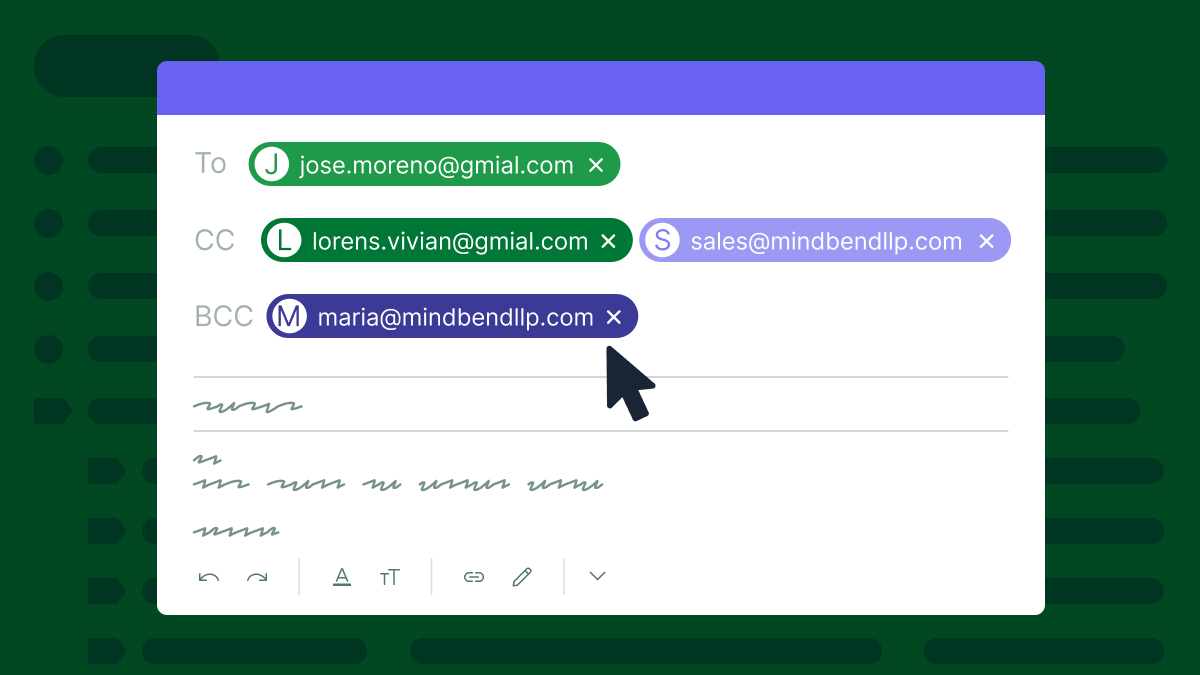

The supply chain is a network of relationships with customers, suppliers, wholesalers, logistics firms or retailers. CRM systems provide a single platform for managing communications with all stakeholders, reducing the likelihood of misunderstandings and fostering stronger partnerships.

A cloud-based CRM further facilitates collaboration between these stakeholders by providing a centralized platform for sharing data and insights. Everyone in the supply chain can get access to the latest information.

Accurate forecasting is critical to effective supply chain management, and CRM systems provide valuable insights and reports covering customer behavior and sales trends. By analyzing customer data, CRM tools help you predict future demand more accurately.

Ultimately, SCM and CRM both aim to improve the customer experience. A well-managed supply chain ensures customers receive their products on time, while CRM systems help you understand and meet customer needs.

Combining CRM and SCM can improve customer satisfaction by aligning your supply chain operations with buyer expectations.

Final thoughts

By understanding and optimizing each component of the supply chain, from initial planning to handling returns, you can streamline operations, reduce costs and increase profits.

With the right strategies and tools, including a robust CRM system like Pipedrive, your supply chain can become a powerful asset that gives your business a competitive edge.

Start by assessing your current supply chain processes and looking for potential improvement areas. Even a minor change in the right place can lead to significant long-term benefits for you and your customers.